Call Us Now

+8615914489090

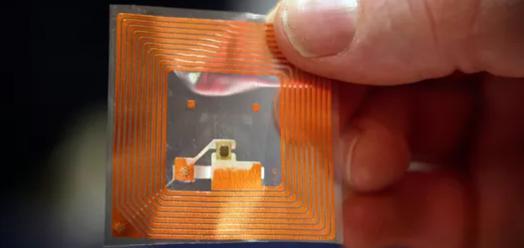

Cheaper, faster and more common RFID and sensor technologies in the logistics supply chain

Sensors and automatic identification have changed the supply chain. RFID tags, barcodes, two-dimensional codes, handheld or fixed position scanners and imagers can generate real-time data, thereby improving the visibility of the supply chain. They can also enable drones and autonomous mobile robots to bring more automation technology into the warehouse.

Chris Riemann, Deloitte's managing director of supply chain and network operations, said the technology "has made great strides."

Companies will continue to invest in these technologies as they are closer to realizing the concept of automated warehouses, especially in the face of unprecedented labor shortages.

In MHI's 2021 "Innovation Driven Resilience" annual industry report, MHI and Deloitte conducted a survey of more than 1,000 supply chain-related companies around the world on supply chain innovation investment. They found that 52% of companies are increasing or substantially increasing their investment in sensors and automatic identification. Among the respondents, 42% said they now use sensors and automatic identification, and 27% plan to adopt the technology within one to two years.

Riemann said that this popularity is driven by two factors: better technology and lower cost.

01

Cheaper, more advanced tags provide a complete inventory view

When Riemann first saw RFID tags 20 years ago, "There was a lot of publicity at the time, but technology and physics did not exist, and of course the price did not exist."

He assumed at the time that to make this technology ubiquitous, each tag would cost about 5 cents. According to real-time location system (RTLS) Airfinder data, this 5-cent assumption is not far from him, because some tags in the low-end market are 10 cents each.

More advanced and cheaper tags implement various functions in warehouse and retail environments. These labels let the retailer know exactly which stores have what inventory, and where the inventory is. This gives them more sales options.

For example, if a retailer knows what's in a particular store, it can allow customers to order the item, choose to buy it online, pick up the item at the store, and deliver the item there when the customer arrives.

"If customers shop online, the inventory shows that I have this product, but in fact we really don't have it. This is a big problem." Riemann said. Especially if a customer discovers this after going to a retail store, mistakes like this may cause the store to lose a loyal customer.

Sensors and automatic identification also help companies track losses by letting companies know "the exact location of the product at any point in time." This is even more important if the product eventually enters the black market or gray area.

Riemann said that if a product accidentally appears on a flea market at a thrift store or an online shopping auction site eBay, the retailer can query the RFID tag and determine where it is missing, and find the problem point in its supply chain, whether it is a supplier. Move some inventory to sell, or employees buy goods at discounted prices in stores and sell them online.

02

Data processing speed has been improved

Kyle Bermel, chief operating officer of Metalcraft, a supplier of industrial nameplates and labels, said that cameras have also become faster and better at processing data collection.

The RFID tag itself is more sensitive, "the integrated circuit that powers the RFID tag has better performance and can create a smaller layer." This has reduced costs, but recent supply chain issues have prompted a rebound in costs.

Bemel expects that dual-frequency RFID tags will be more widely used, which means that warehouses can use UHF functions on tags and readers for far-field reading, and anyone with a smartphone can communicate through near-field Visit the label.

This technology has almost unlimited possibilities.

"You can use your smartphone to lean against the label to see what the temperature is, or what the temperature is in the past." The company can also bring such label products to promotional activities and allow potential customers to use their mobile phones to lean against the label. to know more information.

03

Vision robots are next

Adrian Kumar, vice president of global logistics group DHL supply chain solution design, said that DHL deployed the trajectory robot AMR for the first time in 2017. In 2020, DHL expanded its robot deployment.

During this time, AMR has improved, especially in terms of achieving better visual recognition. "AMR can see farther away and they can pick up more things. Because the price of sensors has dropped, they can install more sensors on the robot so it will become smarter."

Kumar predicts that sensors are getting better, and as sensors become cheaper, the more things that can be installed on AMRs, the more robots can work with humans instead of just being fixed in specific areas.

Riemann said: "I went to the supermarket shelf, saw corn flakes, and then I picked corn flakes. This is intuitive for me. But it is not intuitive for robots."

And this is the next step in robotics innovation.